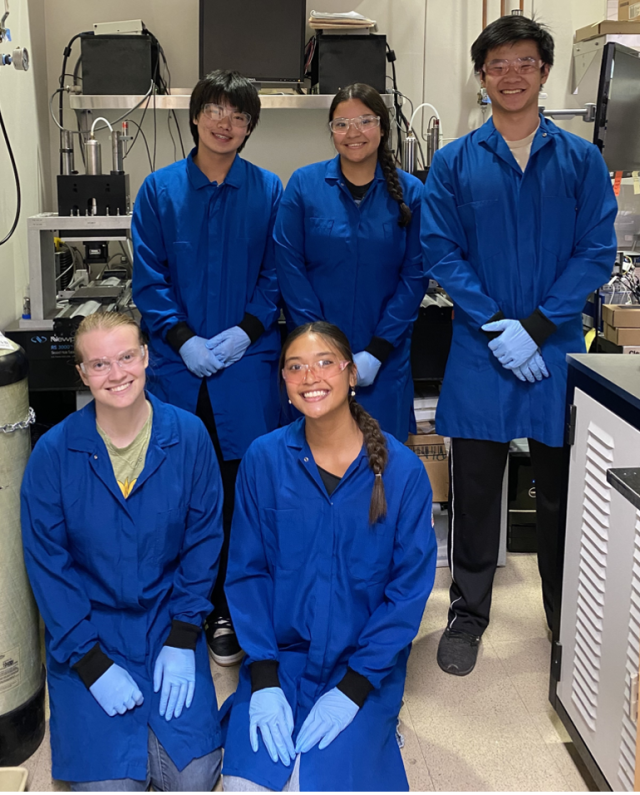

Advisor

Dr. Angela Pitenis - Materials Science & Engineering

Mentor

Katie Shaffer - Materials Science & Engineering

Slippery Solids: Designing PTFE Composites for Low Friction and Wear

Interns

Chen Hui Lin - Computer Engineering

Jennalyn Mejia - Mechanical Engineering

Alex Zhang - Chemical Engineering

Samantha Lund - Biopsychology

Project Description

From balding tires to worn-out gears, friction and the wear that it causes pervades many aspects of our everyday lives; on a global scale, the cost required to sustain these high friction interactions as well as replace worn-out materials adds up to $2.87 trillion. To reduce this cost, our research focuses on extending the lifespan of sliding interfaces through the use of solid lubricants, which are low friction materials that are inserted between these interfaces. The plastic polytetrafluoroethylene (PTFE) is a commonly used solid lubricant with low friction but high wear. To improve this solid lubricant’s wear resistance, we mixed the additive cobalt blue into a sample of PTFE using ultrasonic vibrations. To test our newly synthesized material, we measured its wear rate and coefficient of friction on a sliding machine called a tribometer. Relative to pure PTFE, the wear rate of our new material was 118% lower at the cost of a 30% increase in friction. In this light, our research demonstrates how additives can be used to optimize solid lubricants, and subsequently, increase the productivity of their use. In our future work, we will test and compare the effectiveness of other additives to further reduce friction and wear.